More than a service, a quality experience

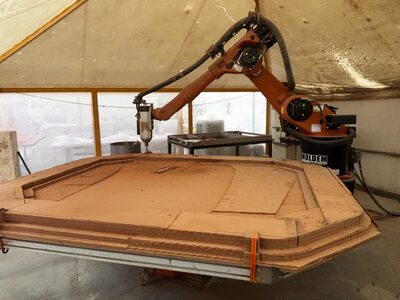

Engineering, cutting, modeling and detailing with a passion for excellence

Moldem is a company specialized in the manufacturing and repair of reinforced engineering plastic components, committed to quality, innovation, and personalized service. Our technical expertise allows us to understand and address the specific needs of each client

through customized, efficient, and sustainable solutions.

Quality Service

We strive for quality in manufactured parts, maximum availability of production systems, and stable processes.

Guaranteed Commitment

We are a solid and reliable partner when it comes to selecting the right solution to meet customer needs.